Ensure DC motor performance with anomaly detection based on energy monitoring

The challenge

Optimizing manufacturing processes is a requirement in any industry today, with electricity consumption in particular representing a major concern due to increased costs and instability. Analyzing energy use has therefore become a widespread need – and one that can also lead to early identification of anomalies and predictive maintenance: two important activities to put in place in order to minimize unexpected downtime and repair costs.

In particular, this approach can be applied to DC motors: used in a wide range of applications, from small household appliances to heavy industrial equipment; these motors are critical components that require regular maintenance to ensure optimal performance and longevity. Unfortunately, traditional maintenance practices based on fixed schedules or reactive repairs can be time-consuming, expensive, and unreliable. This is where energy monitoring-based anomaly detection comes in: it can provide a crucial solution for the early detection of potential issues and malfunctions before they can cause significant damage to the motor.

This more proactive approach to maintenance continuously monitors the energy consumption of the motor and analyzes the data to identify any deviations from normal operating conditions. By tracking energy usage patterns over time, the system can detect early warning signs of potential problems, such as excessive wear and tear, imbalances or misalignments, and alert maintenance personnel to take corrective actions before the issue escalates.

Our solution

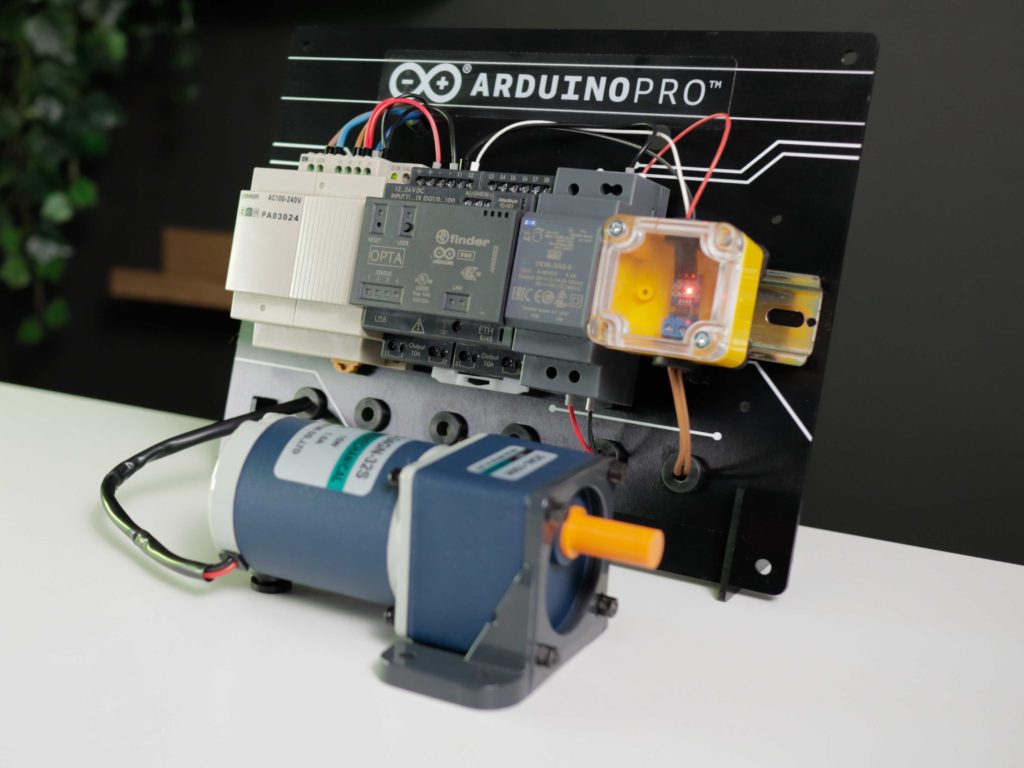

This Arduino-powered solution implements an energy monitoring-based anomaly detection system using a current sensor and machine learning models running on edge devices. By capturing the electricity flowing in and out of a machine, it can collect large amounts of data on energy usage patterns over time. This data is then used to train a machine learning model capable of identifying anomalies in energy consumption behaviors and alerting operators to potential issues. The solution offers a cost-effective and scalable method for maintaining equipment health and maximizing energy efficiency, while also reducing downtime and maintenance costs.

Motor Current Signature Analysis (MCSA)

In this application, a technique called motor current signature analysis is used. MCSA involves monitoring the electrical signature of the motor’s current overtime to detect any anomalies that may indicate potential issues or faults. To acquire real-time data, a Hall effect current sensor is attached in series with the supply line of the DC motor. The data are then analyzed using machine learning algorithms to identify patterns and trends that might indicate a faulty motor operation. MCSA can be used to detect a number of issues like bearings wear, rotor bar bendings or even inter-turn short circuits.

Depending on the dimensions of the motor, using a non-invasive clamp-style current sensor – also known as a split-core current transformer – is recommended if a larger current draw is expected.

Edge ML

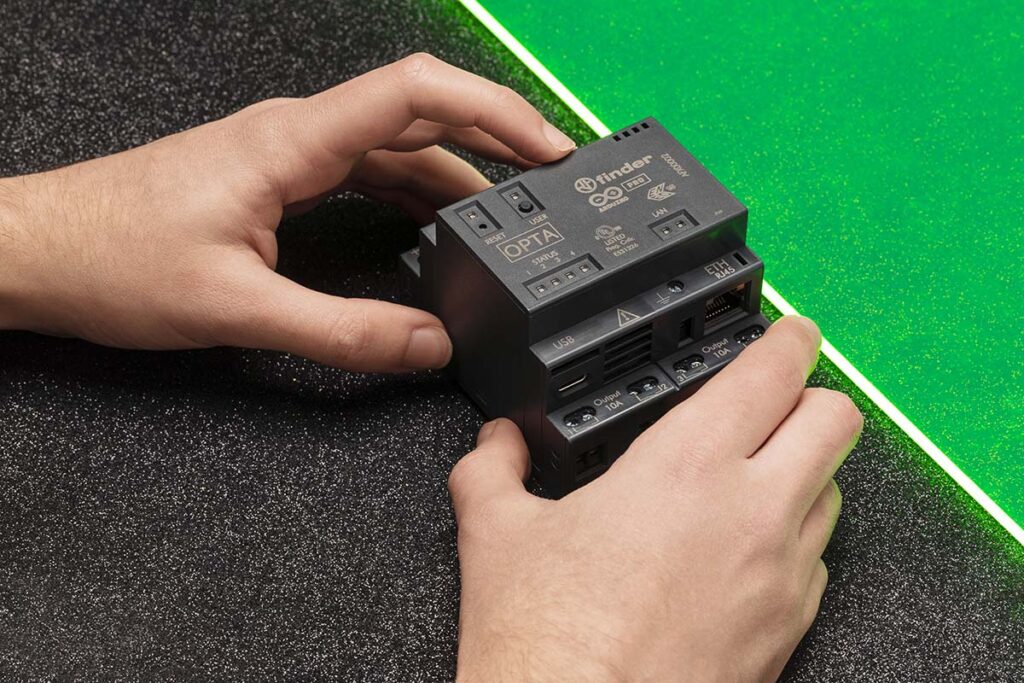

To monitor the current fluctuation and run the anomaly-detecting ML model, the solution uses an Arduino Opta WiFi: a micro PLC suitable for Industrial IoT, which is excellent for this project because of its real-time data classification capabilities, based on a powerful STM32H747XI dual-core Cortex®-M7 +M4 MCU. The Arduino Opta WiFi works with both analog and digital inputs and outputs, allowing it to interact with a multitude of sensors and actuators. The Arduino Opta WiFi also features an Ethernet port, an RS485 half duplex connectivity interface and WiFi/Bluetooth® Low Energy connectivity, which makes it ideal for industrial retrofitting applications. You can find the full datasheet here.

To train the anomaly detection model, the project leverages the Edge Impulse platform: being integrated within the Arduino ecosystem, it makes it easy to develop, train, and deploy machine learning models on Arduino devices.

Connectivity

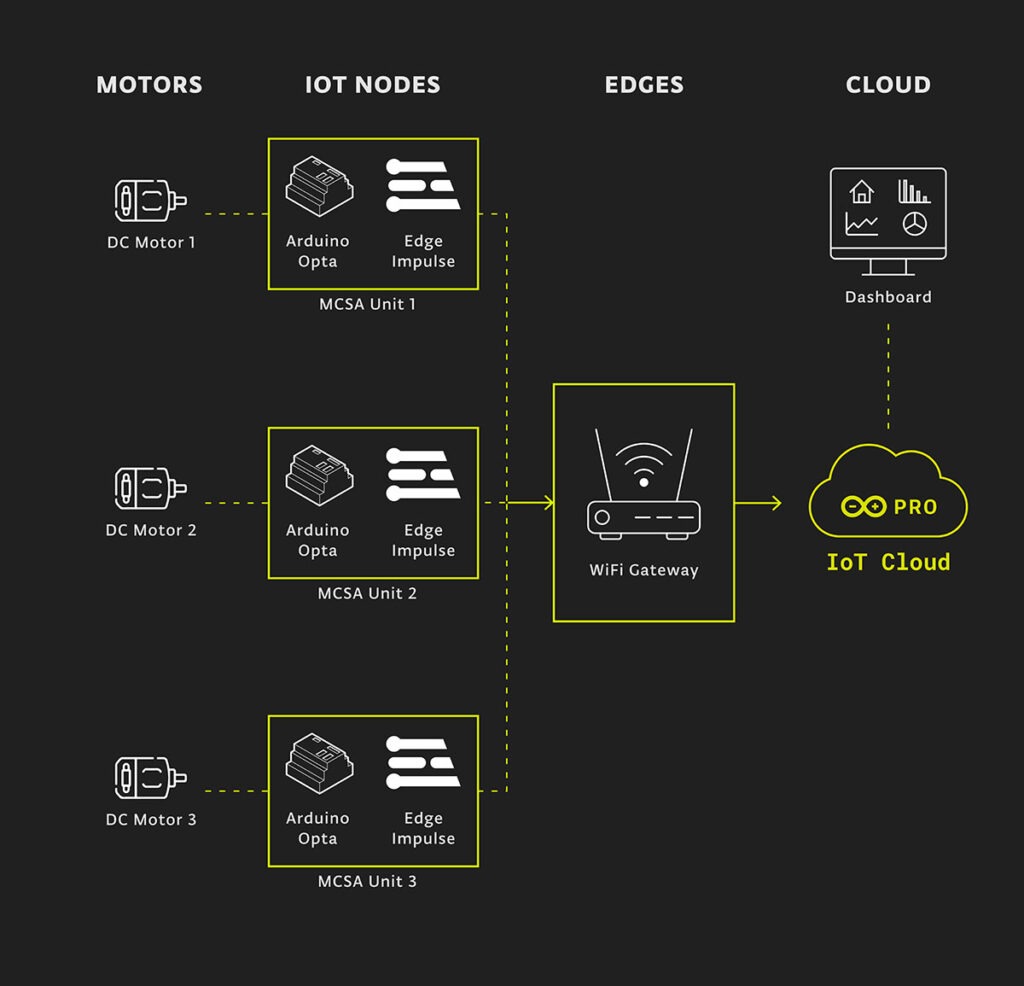

Once the machine learning model was successfully deployed on the Arduino Opta, the anomaly detection results were forwarded via WiFi to the Arduino IoT Cloud. This enables easy monitoring and analysis of the data from multiple sensor nodes in real-time.

Solving it with Arduino Pro

Let’s take a look at how we can put all of this together and what hardware and software solutions we would need for deployment. The Arduino Pro ecosystem is the most recent version of Arduino solutions, offering users the benefits of easy integration along with a range of scalable, secure, and professionally supported services.

Hardware requirements

- Arduino Opta WiFi

- DC current sensor

- Enclosure

Software requirements

- Arduino IDE 2.0

- Edge Impulse account

- Arduino Cloud account

The Arduino IDE 2.0 was used to program the Arduino Opta WiFi using C/C++. To train the Edge Impulse model, data was gathered from the current sensor for two classes: Normal Operation and Machine Off. The motor current signature analysis (MCSA) technique was implemented by extracting the frequency and power characteristics of the signal through a Spectral Analysis block. Additionally, an anomaly detection block was incorporated to identify any abnormal patterns in the data.

Here is a screenshot from a dashboard created directly in the Arduino Cloud, showcasing data received from the sensor nodes:

Here is an overview of the software stack and how a minimum deployment with one of each hardware module communicates to fulfil the proposed solution:

Conclusion

Through the implementation of a predictive maintenance system on an Arduino Opta WiFi PLC, using Edge Impulse ML models and the Arduino Cloud, this solution demonstrates the powerful potential of IoT technologies in industrial applications. With the use of current sensors and AI-driven anomaly detection models, the system enables real-time monitoring and fault detection of DC motors, providing valuable insights for predictive maintenance. The flexibility and scalability of the Arduino Opta WiFi platform make it a robust and cost-effective solution for implementing predictive maintenance systems in various industrial processes. Overall, the project highlights the significant advantages that MCSA and machine learning can offer in promoting efficiency, productivity, and cost savings for industrial processes.