Reconstruct core samples virtually from sand with the Magic Sand Slicer

FDM 3D printers work by taking a model, creating many thin slices of it, and then extruding plastic to produce the desired shape. But what happens if you want to reverse that process, e.g. take many tiny slices of something and build a model digitally? This is commonly done with medical imaging device such as MRI machines, but Danilo Roccatano wanted to design a much smaller and cheaper version that works with sand.

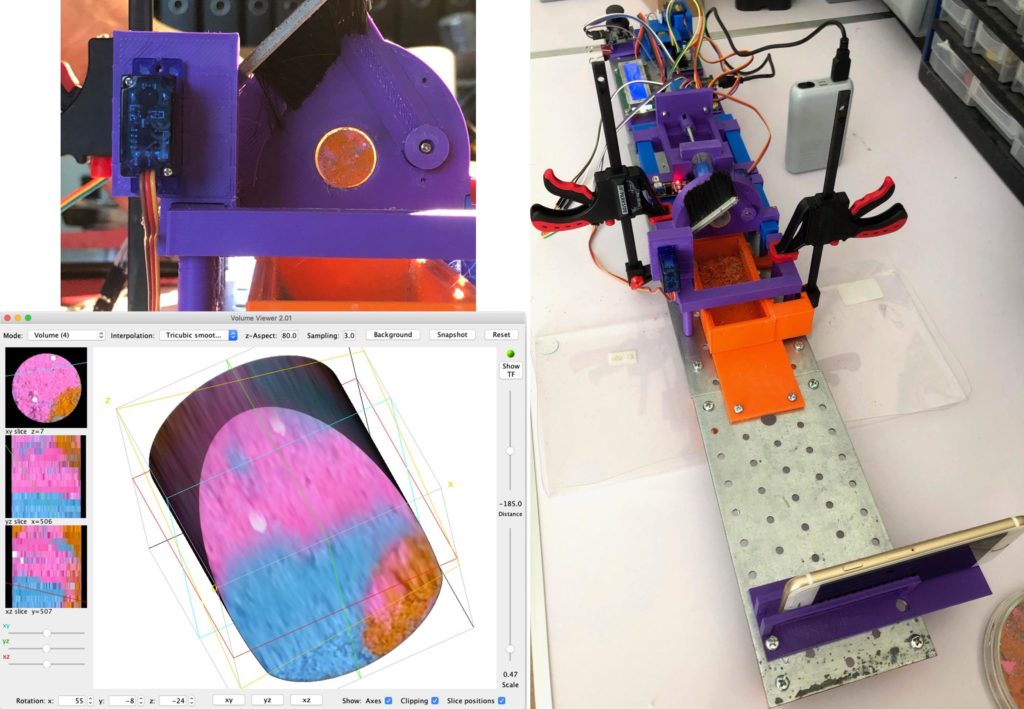

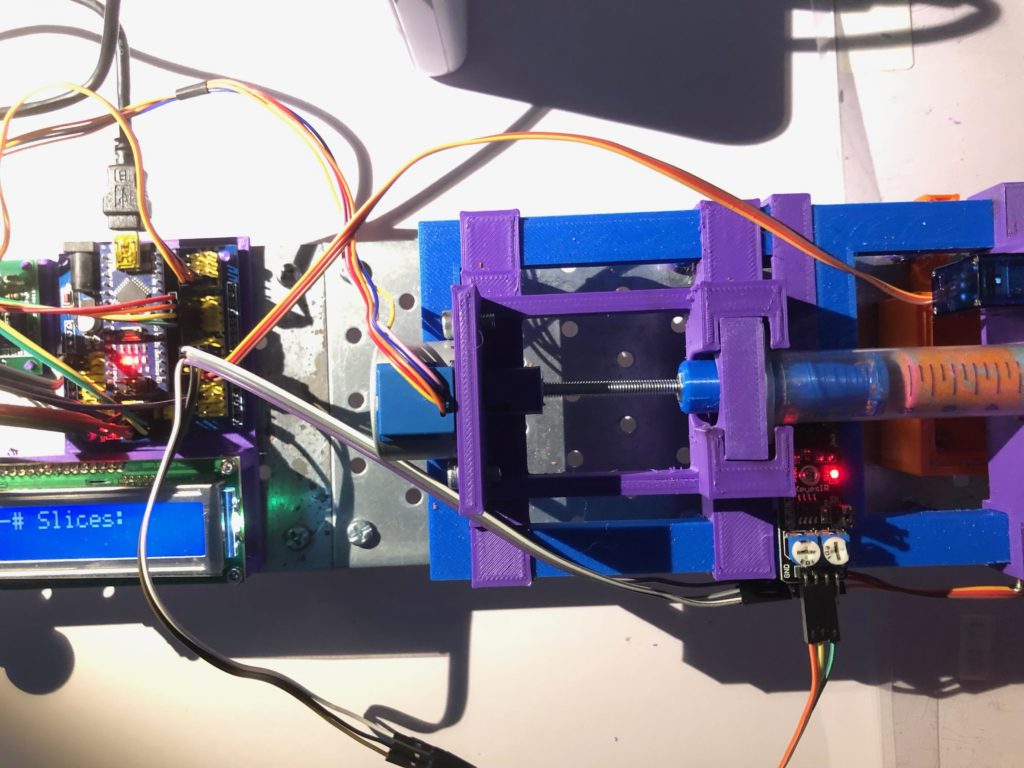

His device, which he calls the Magic Sand Slicer, works just as the name implies. Core samples of wet, colored sand are taken from a larger vessel and then placed into an extruder. Next, a 5V stepper motor rotates a long screw that pushes the plunger of the syringe, thus causing sand to extrude at a constant rate. A brush then cleans the surface to make it smooth and a smartphone camera takes a picture. A single Arduino Nano manages everything from the motors to the IR limit switch.

With all the pictures taken, each one is cropped to just its cross-sectional area and then passed to a program called ImageJ which uses those 2D images to create a 3D model. This colorful model can be zoomed, rotated, panned, and sliced virtually, allowing the user to see every intricate detail within their sample. Eventually, Roccatano wants to expand this functionality to other mediums such as rocks and insect-made tunnels.

You can read more about this project in Roccatoan’s write-up, which was recently named a runner-up in Instructables’ Arduino Contest.