Using Arduino on industrial digital printing machines

Most of the projects we’ve been featuring on this blog are happen to be focused on diy approaches around music, design, art. We are noticing that more and more people are starting to realize the benefits of using Arduino also in industrial settings.

Today I’m going to highlight a project posted by Paul M Furley on his blog and describing how back in 2009 he worked in a family firm, producing the user operator software for their new digital printing machine and decided to use Arduino in high-tech manufacturing:

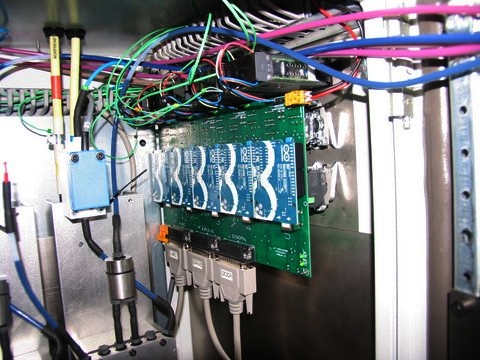

I’d been hacking around with Arduino since my masters project and it came along at a perfect time for JF Machines. They had just developed their new ink circulation system: a serious affair with 5 separate ink bottles rising and falling to alter pressure along with precise temperature control. They needed a way to drive the bottle lifting motors, read in alarm signals and switch inputs as well as output various flashing sequences for the benefit of the operator. Although a PLC would have been suitable, Arduino seemed like a great option.

Since then he realized why he made the right choice and lists a number of the reasons useful to explore.

You can read the complete story on his page, here’s just a couple of the most interesting benefits:

Supply security – even if Arduino stopped supplying boards tomorrow, other manufacturers are making clones, and the hardware design lives on. If Arduino changed their physical design, it wouldn’t be much trouble to make a converter to adapt the new and old sockets – in fact, someone would probably release it was an off-the-shelf project as soon as the announcement was made! In the worst case scenario, JF Machines could manufacture the whole Arduino board from the designs for as long as the a compatible microcontroller remained available.

Low cost – I often hear the opposite argument when discussing Arduino with the hobby and hacker scene. I agree that for integrating into a consumer product, the Arduino’s off-the-shelf price is fairly expensive (although good luck designing and making a small batch yourself for cheaper…). However when integrated in a five-figure industrial printing machine, the cost comes close to zero, especially when considering the PLC alternative and the support benefits. If JF Machines were ever to mass-produce their machines, reducing the price of the Arduino would be fairly low on the list of priorities!

If you have a similar story and want to share it, we’d be happy to feature it on the blog, just submit it on this page.

July 4th, 2013 at 14:24:25

Supply security is extremely important. I tried to do things with microcontrollers back in the 90s, and whenever I found one that was technically perfect, I got a little note from Motorola or whoever saying that they were going to stop production in a few months.

July 5th, 2013 at 05:21:41

This is huge!!!

July 15th, 2013 at 18:04:36

very informative!

<a href="”>LaserNett