Spotting defects in solar panels with machine learning

Large solar panel installations are vital for our future of energy production without the massive carbon dioxide emissions we currently produce. However, microscopic fractures, hot spots, and other defects on the surface can expand over time, thus leading to reductions in output and even failures if left undetected. Manivannan Sivan’s solution for tackling this issue revolves around using computer vision and machine learning to find small defects at the surface before automatically reporting the information.

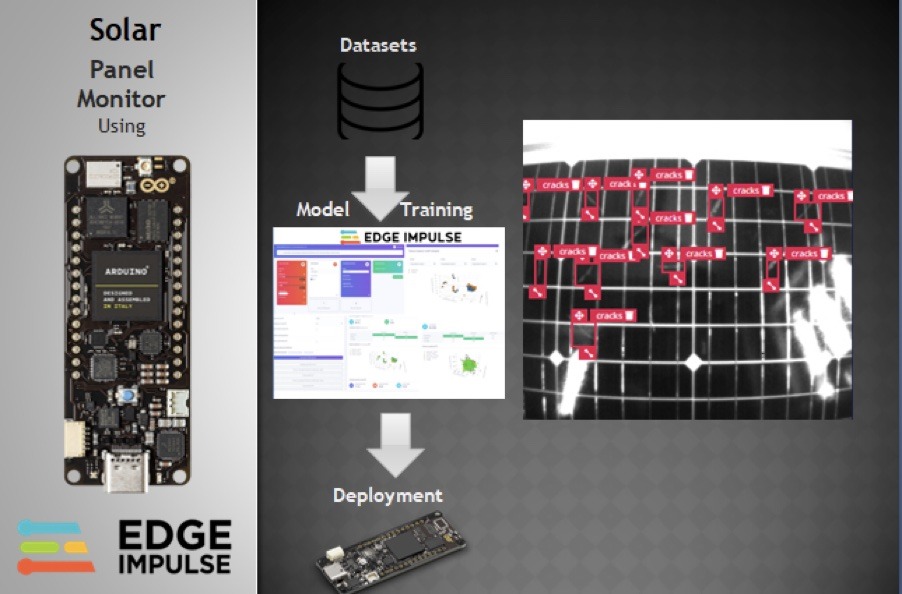

Sivan compiled his dataset by first gathering images of solar panels that have visible cracks using an Arduino Portenta H7 and Vision Shield and then drawing bounding boxes around each one. From here, he trained a MobileNetV2 model with the addition of Edge Impulse’s recent FOMO object detection algorithm for better performance. He was able to improve the model’s accuracy even further by augmenting the dataset with images taken at different camera angles and lighting conditions in order to prevent mistaking the white boundary lines for cracks.

After testing and deploying the model from the Edge Impulse Studio to his Portenta H7 board, it was able to successfully find cracks in a solar panel’s surface around 80% of the time. In the future, Sivan might add other features that take advantage of the onboard connectivity to communicate with outside services for faster response times. You can read more about the project here.